What is Aluminum Plate?

Generally speaking, aluminum plate is a product formed when aluminum material is pressed and rolled under intense pressure. Generally, the aluminum sheets are lightweight but strong enough to be used for a wide range of applications.

The extreme versatility of the aluminum plates is boosted by the ease of installation and maintenance. This explains why the aluminum sheet is among the most popular metal sheets.

Different types of coatings are applied to the aluminum sheet metal. The purpose of coatings is to increase the strength and durability of the aluminum sheets. They also make the sheet applicable to different conditions.

There are different surface finishes of the aluminum metal sheet. Some a/re smooth and uniformed while others are rough or rugged. The choice of the aluminum plate texture will depend on its application areas.

Aluminum sheet metal comes in different sizes. You are free to choose the size that will perfectly fit your application. All you need is to communicate with the aluminum sheet metal manufacturer and specify the size. As expected, the price will depend on the size of the aluminum metal plate.

Types of Aluminum Plate

Aluminum sheet metals are not all the same. They come in different forms. Here are the types of aluminum sheet metals that you will find in the market.

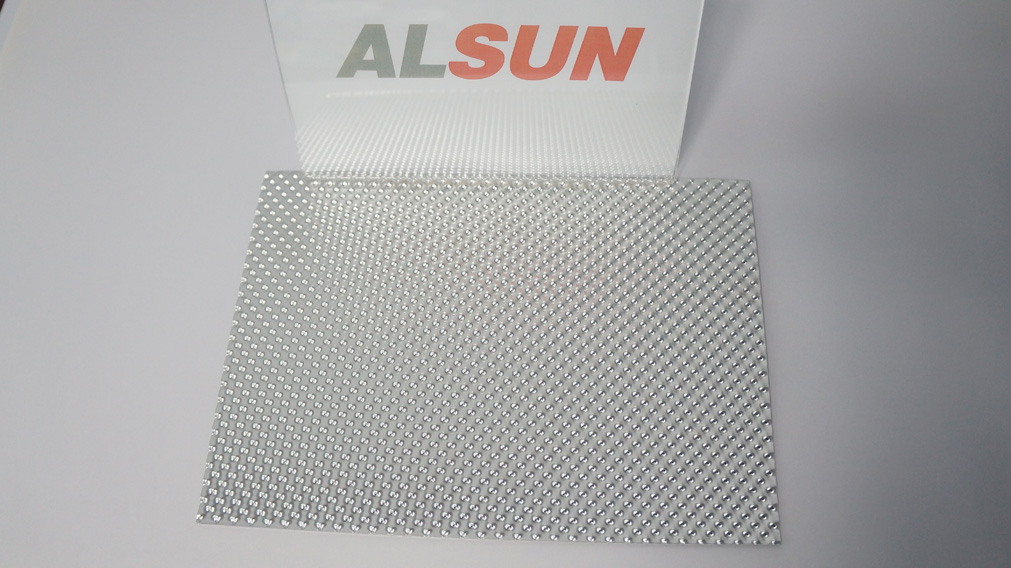

1. Checker aluminum sheets

As the name suggests, this type of aluminum sheet is characterized by numerous raised hatch marks on one side and the other side remains untextured marks. Some people call these aluminum sheets to tread plates durbar floor plates and bar sheets.

These aluminum sheets are sturdy and can withstand high-impact force. They are perfectly suited for both interior and exterior applications. Because of their strength and sturdiness, you can use them for heavy-duty applications. These include loading bays, car parks, flooring systems service corridors among others.

2. Brushed aluminum sheets

Almost all the aluminum sheet metal exists in two forms. They are either brushed or unbrushed. In this context, we are using brushed to mean that the metal sheet ha a fairly uniform pattern. Alternatively, some have light scratches and scuffs that are uniform and parallel to each other.

This type of aluminum sheet metal is also ideal for creating aesthetic effects. They are stylish and well-polished. You can use them to accentuate your interior design ideas. They are applicable to both domestic and industrial applications.

3. Composite aluminum sheet

This type of aluminum sheet is usually abbreviated as ACS. It comprises pieces of coil-coated aluminum that are bonded to the non-aluminum core which in most cases in plastic. They are among the lightest aluminum sheets metal in the market.

Composite aluminum sheets are also robust since they carry minimal weight. This feature makes them an ideal choice for external cladding. Because of this, they are sometimes known as dibond sheets or sandwich panels.

Their lightweight also makes it easy to install and maintain. They can be easily cut and shaped for different applications. Some of their applications include cladding and decorations

4. Anodised Aluminium Sheets

In chemistry anodising is a process of introducing a layer of oxygen onto the metal sheet hence increasing its thickness. This means that anodised aluminum sheets have an oxygen layer. The goal of this layer is to increase the resistance of the metal from the effects of wear and tear. It can also be used for increasing the adhesiveness of the metal, especially hen you want to attach other chemicals such as glue and paints onto it.

Anodised aluminum sheet metals are commonly used for decorations. This is because they tend to create strong bonds with other materials.

| Items | Parameters |

|---|---|

| Standard | ASTM, AISI, SUS, EN, JIS, DIN, GB ASME |

| Related grade | 1060, 1050, 1070, 1100, 3003, 3004, 5052, 5652, 5154, 5254, 5454, 5083, 5086, 5056, 5456, 2024, 2014, 6061, 6063. etc |

| Surface | Hairline ,oxidation ,mirror ,embossed ,etc |

| Thickness | 0.15m~280 mm |

| Width | 600-2800mm,or be required |

| Length | 1000-12000mm, or as required |

| Application | 1. Lighting 2, solar reflector plate 3, architectural appearance 4, interior decoration: ceiling, metope, furniture, cabinets and so on 5, plate, nameplate, bags 6, automotive interior and exterior decoration 7. Interior decoration: such as photo frame 8.household appliances, refrigerator, microwave oven, audio equipment, etc. 9. Aerospace and military aspects, such as China’s current large aircraft, the shenzhou spacecraft series, satellite, etc. 10, machinery parts processing, mold manufacturing |

Key Properties of Aluminum Plate

Before buying aluminum sheet metal, you should know the key elements that characterize this metal. Here are some of the most noticeable benefits of aluminum sheet metal that you should know:

-Lightweight: The Aluminum sheet is among the lightest metal sheets in the market. In terms of comparison, it is 1/3 the weight of a steel sheet. This property comes with numerous advantages. You can handle the metal sheet with total ease.

-Strong: Despite being lightweight, aluminum sheet metal is quite strong. Its strength makes it usable for industrial applications. This advantage of the aluminum metal sheet also makes them durable and cost-effective

-Resistant to corrosion: Can aluminum metal sheet corrode? This is a question that you may ask yourself. Aluminum is among the metals types that don’t corrode so easily. It will only corrode if subjected to extremely aggressive conditions.

-Easily formable: Aluminum sheet metal has a relatively low melting point. This means that it can be easily formed into different shapes when subjected to a certain level of heat.

-Suitable for sensitive applications: Aluminum sheet metal can be used for sensitive applications such as chemicals and food packaging. They are used because they don’t react easily with other materials.

You won’t have to worry about the flavor of the food being affected by the aluminum sheet container.

-Fireproof: Will the aluminum sheet burn? Aluminum sheet metals don’t burn when exposed to flames of fire. Only a thin layer of the metal sheet will get affected. They also don’t release toxic gas when exposed to heat.

-Has reflective properties: An aluminum sheet metal can reflect the light and even heat away from its surface. This property makes it an ideal choice for lighting applications.

-Recyclable: The most popular advantage of aluminum metal sheets is the ability to be recycled. Most aluminum metals that are in use today are a product of recycling.

– Available in different thickness: The flexibility of the aluminum metal sheet makes the available in various dimensions. You can choose different size and thickness of the metal sheet.

Series of Aluminum Plates

1000- series 1050, 1050A, 1060, 1085, 1145, 1070, 1100, 1350, 1200, 1235, 1060, 1A99, maily used in cosmetic caps, checker plates, cabinet sheet, lighting component stock, conductive materials, etc.

2000- series 2A12, 2024, 2014, 2017 mostly used in qunched plate, pre-streched plate.

3000- series 3003, 3004, 3005, 3104, 3105, 3A21 normally applied in battery shell, Pressure container, anodizing stock, honeycomb materials, etc.

4000- series 4004, 4104, 4343 mainly used in caldding foil sheet and plate.

5000- series 5A03, 5A05, 5052, 5052A, 5252, 5005, 5083, 5059, 5086, 5182, 5251, 5056, 5754, 5A06, 5454, 5042 Mainly applied in Anodizing materials, checker plates, elastic caps, transportation tab, automotive cover structure for new energy vehicles.

6000- series 6M63, 6M61, 6Y13, 6061, 6063, 6A02, 6082, 6016, 605A, 6101 Used in qunched plate, composite board, car doors, etc.

7000- series 7072,7075 used in Qunched plate, pre- stretched plate, etc.

8000- series 8011, 8021, 8079, 8006 applied in Beverage foil, cable foil, pharmaceutical foil, blister foil, etc.

Applications of Aluminum Plate

By being a versatile metal, aluminum metal plates have a wide range of applications. The uses of the aluminum plates range from large scale applications to the small and sensitive uses.

Aluminum plates have found their usefulness in different areas You can without much of a stretch see aluminum plates being utilized on vehicles for its bodies and for framing. You can likewise observe aluminum plates used for packaging in the food and beverage industry, and as parts of cookware and apparatuses.

Plates of aluminum can likewise be seen being utilized by the construction and building industry through the material, drains, sidings and such.

Aluminum plates are likewise perfect for use with the making of metal nameplates and other comparative things. Number plates for vehicles are regularly made of aluminum plates for the most part in light of the fact that they are lightweight and come at reasonable costs. These are likewise utilized because of their corrosion resistance and require fairly minimal maintenance.

The uses of aluminum plates will in most cases depend on its thickness. Thinner aluminum plates being utilized for small scale applications. It is at this point that the importance of aluminum plate metal gauge comes in. You can use it to know the thickness of the plate and know whether it will fit into your application.

Top 3 Aluminum Plate manufacturer

1. Aluminum Corporation of China Limited (“Chalco”)

Chalco was incorporated on September 10th, 2001 in China, Chalco is its controlling shareholder. Chalco is a leading company in China’s non-ferrous industry, with a strong portfolio of assets among global competitors. It is also the only large company in China’s aluminum industry that’s engaged in the whole value chain, from exploration and mining of bauxite and coal, the production, sales, and R&D of alumina, primary aluminum and aluminum alloy products, to international trade, logistics, and power generation from both fossil fuels and new energy. Currently Chalco has 39 subsidiaries, 18 wholly owned and 21 controlled ones. Chalco has been listed in the New York Stock Exchange (stock code: ACH), the Stock Exchange of Hong Kong (stock code: 2600), and Shanghai Stock Exchange (stock code: 601600).

2. Aluminum corporation of America (“Alcoa”)

Alcoa Corporation (a portmanteau of Aluminum Company of America) is an American industrial corporation. It is the world’s eighth largest producer of aluminum, with corporate headquarters in Pittsburgh, Pennsylvania. Alcoa conducts operations in 10 countries. Alcoa is a major producer of primary aluminum, fabricated aluminum, and alumina combined, through its active and growing participation in all major aspects of the industry: technology, mining, refining, smelting, fabricating, and recycling.

3. Emirates Global Aluminium (“EGA”)

Emirates Global Aluminium is the world’s largest ‘premium aluminium’ producer and the biggest industrial company in the United Arab Emirates outside oil and gas. Emirates Global Aluminium’s product range includes more than 330 individual primary aluminium products that are made to customer specifications, and most of our aluminium is allocated to customers a year in advance.

Transport of Aluminum Plate

For aluminum plates and coils, packaged in apecial papers and wooden support firsly, then loaded into the containers with the fasten measures.

20 FT Internal (L x W x H) 6010mm x 2340mm x 2390mm

40 FT Internal (L x W x H) 12110mm x 2340mm x 2390mm

40 HC Internal (L x W x H) 12110mm x 2340mm x 2690mm

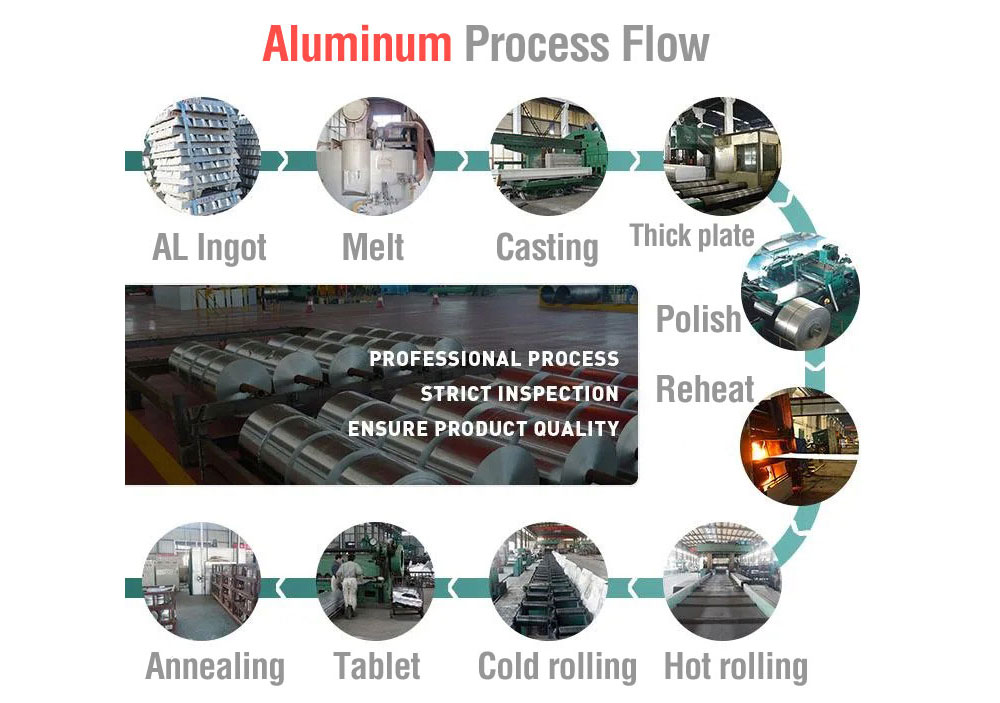

Aluminum Plate Manufacturing processing

The whole aluminum production line start from the aluminum ingots, the aluminum block will be taken to the casting machine after melting in the melting equipment. After shaping the block to the thick plates, polishing in the special device, the aluminum thick plates are reheated in the furnace.

After hot rolling, cold rolling, the thick aluminum sheets will be tabletted into the smaller and thin pieces, the final procuts will be packed after the annealing.